| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® Max | 5.00 |

| A | C12-15 Alkyl Benzoate | 26.50 |

| A | Octyldodecanol | 30.00 |

| A | OleoShine® Green | 7.00 |

| A | Pigment | 15.00 |

| B | Carnauba Wax | 8.00 |

| B | Candelilla Wax | 8.00 |

| C | Fragrance | -2.5 |

Heat A to 90°C and stir for 30 minutes

Cool to 80°C

Add B and C successively, and mix well

Pour at 80°C

Provides a glossy, luminous finish

Glides on easily

Keeps lips hydrated and soft

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® M | 5.00 |

| A | Caprylic/Capric Triglyceride | 28.00 |

| A | OleoFilm® Green | 3.00 |

| A | OleoShine® Green | 20.00 |

| A | Candelilla Wax | 7.00 |

| A | DISM | 20.00 |

| A | Pigments | 2.00 |

| A | Cosmedia Gel CC | 8.50 |

| B | Silica | 5.00 |

| C | Fragrance | 0.50 |

Heat A to 100°C and stir for 30 minutes

Cool to 60°C

Add B and C successively, and mix well

Pour at 60°C

Lightweight, smooth, and easy to apply

Leaves a luminous, healthy glow

Soft, Comfortable Feel

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | OleoShine® Green | 30.00 |

| A | Octyldodecanol | 35.80 |

| A | Premium Organic* Apricot Butter | 4.00 |

| A | Beeswax | 5.00 |

| A | Dicaprylyl Carbonate, Stearalkonium Hectorite, Propylene Carbonate | 15.00 |

| A | EstoGel® Green | 2.00 |

| B | Glyceryl Behenate | 6.00 |

| C | Pearls | 1.00 |

| D | Fragrance | 0.70 |

| D | Fragrance | 0.50 |

Heat A to 80°C and stir for 20 minutes

Add B under high shear and stir for 5 minutes

Cool to 60°C with moderate stirring

Add C and D successively, and mix well

Pour at 60°C

Highly Nourishing

Smooth, protective, non-sticky, comfortable

Beautifies the lips

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | OleoShine® Green | 40.00 |

| A | Caprylic/Capric Triglyceride | 23.58 |

| A | Castor Oil | 20.00 |

| A | EstoGel® Green | 0.80 |

| B | Macadamia Oil | 10.00 |

| C | Fragrance | 0.80 |

| D | Ricinus Communis (Castor) Seed Oil, CI 45410 | 3.92 |

| D | Carrot Bio Extractive | 0.60 |

| D | Pigment | 0.30 |

Heat A to 80°C and stir for 20 minutes

Cool down to 30-35°C

Add B, C, and D successively, mixing well

High shine

Enveloping texture

Comfortable and nourishing

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | NWD-8462 Titanium Dioxide | 12.00 |

| A | NWD-7336 Red Iron Oxide | 8.00 |

| A | OleoFilm Green | 4.00 |

| A | Cosmedia Gel CC | 10.00 |

| A | Dimer Dilinoleyl Dimer Dilinoleate | 10.00 |

| A | EstoGel® Green | 1.00 |

| B | Isododecane | 39.20 |

| C | Silica | 10.00 |

| C | Magnesium Myristate | 5.00 |

| D | Tocopherol | 0.30 |

| D | Fragrance | 0.50 |

Add A to a beaker and heat up to 80°C under stirring

At 80°C, unfold the polymer under stirring for 20 minutes

Cool to 60°C

Add B and mix well

Add C and homogenize

Add D and mix well

Zero transfer and fast-drying formula, ensuring a smooth and matte finish

Even dispersion, providing consistent color and coverage

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | Polyglyceryl-2 Isostearate/Dimer Dilinoleate Copolymer | 40.00 |

| A | Caprylic/Capric Triglyceride | 28.00 |

| A | Castor Oil | 20.00 |

| A | EstoGel® Green | 0.8 |

| A | Macadamia Oil | 10.00 |

| B | Fragrance Vanille Gourmande | 0.70 |

| C | Pigments (sol. 1% in Caprylic/Capric Triglyceride) | 0.45 |

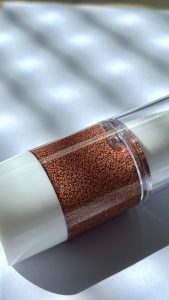

| C | SunSHINE® Ultra Glitter Bronze | 0.05 |

Heat up A to 80°C under stirring

At 80°C, disperse the polymer for 20 minutes

Cool to 35°C under stirring

Add B and stir until the blend is homogeneous

Add C and stir until the blend is homogeneous

Pour into a suitable packaging

A repairing lip oil with a rich coating for the lips. Perfect suspension of glitters and pigments and glossy finish for a plumped-up effect.

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | Demineralized Water | 58.00 |

| A | Euxyl® PE 9010 | 0.80 |

| A | Alcohol | 5.00 |

| A | Glycerin | 5.00 |

| B | Demineralized Water | 25.00 |

| B | ExpertGel® EG312 | 3.50 |

| C | CI 17200 | 0.20 |

| D | Polysorbate 20 | 2.00 |

| D | Fragrance | 0.50 |

Unlike standard lip inks, this product does not dry out the lips, and ExpertGel® ensures perfect definition of the product on the lips and no migration of the colour into fine lines.

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® M | 4.00 |

| A | Castor Oil | 70.00 |

| A | Caprylic/Capric Triglyceride | 12.85 |

| A | Dimer Dilinoleyl Dimer Dilinoleate | 12.00 |

| B | NWD-8462 Titanium Dioxide | 0.07 |

| B | NWD-7336 Red Iron Oxide | 0.01 |

| C | Sunshine® Soft Bronze | 0.02 |

| C | Sunshine® Ultra Glitter Bronze | 0.05 |

| D | Fragrance | 1.00 |

Coating and non sticky gloss that beautifies the lips.EstoGel® M acts as a texturizing agent that keeps the pearls in suspension.

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® Max | 55.00 |

| A | COD-8002 D&C Red 6 Ba Lake | 3.20 |

| A | COD-8001 D&C Red 7 Ca Lake | 12.80 |

| A | Caprylic/Capric Triglyceride | 23.40 |

| A | Hazelnut Oil | 5.00 |

| B | Fragrance | 0.60 |

An ultra shiny lipstick without wax with a very melting and glide-on application.

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® M | 5.00 |

| A | Castor Oil | 29.30 |

| A | Caprylic/Capric Triglyceride | 26.50 |

| A | Undecane (and) Tridecane | 10.00 |

| B | Rice Bran Wax | 9.00 |

| C | Candelilla Wax | 7.50 |

| C | Corylus Avellana (Hazelnut) Seed Oil (and) Hydrogenated Hazelnut Oil | 3.00 |

| D | COD-8001 D&C Red 7 Ca Lake | 6.10 |

| D | COD-8009 FD&C Yellow 5 Al Lake | 1.1 |

| D | Sunshine® Blush Bronze | 2.00 |

| E | Fragrance | 0.50 |

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® Max | 50.00 |

| A | Coco-Caprylate Caprate | 27.60 |

| A | Castor Oil | 7.00 |

| A | Isoamyl Laurate | 7.00 |

| B | Castor Oil | 7.80 |

| B | CI 45380 | 0.20 |

| B | Citric Acid | 0 |

| C | Fragrance | 0.40 |

This perfectly transparent stick obtained thanks to EstoGel® Max adapts to the shade of the lips to beautify them.

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® Green | 3.00 |

| A | OleoShine® Green | 5.00 |

| A | Caprylic/Capric Triglyceride | 6.00 |

| A | Ethylhexyl Palmitate | 23.00 |

| B | Oryza Sativa (Rice) Bran Wax | 8.00 |

| B | Euphorbia Cerifera (Candelilla) Wax | 7.00 |

| C | Isohexadecane | 18.00 |

| D | Mica, Titanium Dioxide, Tin Oxide | 10.53 |

| D | Synthetic Fluorphlogopite, Titanium Dioxide | 4.21 |

| D | Synthetic Fluorphlogopite, Titanium Dioxide, Iron Oxides, Tin Oxide | 5.26 |

| E | Silica | 10.00 |

- Heat A to 80°C and stir for 20 minutes

- Add B, C, D and E successively, mixing well

- Pour at 80°C

- Smooth and easy to apply

- Dries to a powdery texture

- Glowing finish

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | Water | 42.20 |

| A | Ethylhexylglycerin | 0.10 |

| A | Phenoxyethanol | 0.90 |

| B | Pigments | 10.00 |

| C | Glycerin | 3.00 |

| C | Xanthan Gum | 0.40 |

| D | Ethylhexyl Salicylate | 5.00 |

| D | Ethylhexyl Triazone | 4.00 |

| D | Diethylamino Hydroxybenzoyl Hexyl Benzoate | 3.00 |

| D | Bis-Ethylhexyloxyphenol Methoxyphenyl Triazine | 3.00 |

| D | Diisopropyl Sebacate | 9.00 |

| D | Diisopropyl Adipate | 9.50 |

| D | Potassium Cetyl Phosphate | 0.90 |

| D | Polyglyceryl-6 Stearate (and) Polyglyceryl-6 Behenate | 4.00 |

| D | EstoGel® Max | 1.00 |

| D | OleoShine® Green | 3.00 |

| E | Fragrance | 1.00 |

Heat D at 90°C and stir for 30 minutes

Prepare A in the main container

Disperse pigments from phase B into phase A for 30 min

Prepare premix of phase C, then introduce into A+B

Heat the aqueous phase to 80°C

Emulsify for 10 minutes by adding D into A+B+C

Cool down to 30-35°C

Add fragrance and mix well

Natural, Radiant Finish

Light, Even Skin Tone Correction

SPF 30 UV Protection (expected)

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | Demineralized Water | 55.00 |

| A | Glycerin | 3.00 |

| A | Sodium Chloride | 1.00 |

| B | Caprylic/Capric Triglyceride | 15.00 |

| B | OleoFilm Green | 3.00 |

| B | EstoGel® Green | 1.00 |

| B | Polyhydroxystearic Acid | 1.00 |

| C | Undecane (and) Tridecane | 9.00 |

| D | Unipure White LC 981 HLC | 4.58 |

| D | Unipure Yellow LC 182 HLC | 1.90 |

| D | Unipure Red LC 381 HLC | 0.70 |

| D | Unipure Black LC 989 HLC | 0.32 |

| E | Polyglyceryl-3 Diisostearate | 2.00 |

| E | Polyglyceryl-2 Dipolyhydroxystearate | 2.00 |

| F | Fragrance | 0.50 |

Add the ingredients of B to the main beaker and heat up to 80°C under stirring

At 80°C, unfold the polymer under stirring for 20 minutes

Cool to 70°C

Add C to B and mix well

Cool to 55°C

Add the pigments to B+C and homogenize

Add E and mix well

Add the ingredients of A into a secondary beaker and heat up to 50°C under stirring

Make the emulsion pouring A into the oily phase and stir for 15 minutes

Cool to 40°C

Add the fragrance and mix well

Anti-transfer properties

Excellent pigment dispersion and good coverage for a flawless finish

Stabilization

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | Demineralized Water | 54.50 |

| A | Sodium Chloride | 1.00 |

| A | Glycerin | 3.00 |

| B | EstoGel® Green | 2.00 |

| B | Caprylic/Capric Triglyceride | 10.00 |

| B | Undecane (and) Tridecane | 9.50 |

| B | Polyhydroxystearic Acid | 0.50 |

| B | NWD-8462 Titanium Dioxide | 13.32 |

| B | NWD-9336 Yellow Iron Oxide | 1.12 |

| B | NWD-7336 Red Iron Oxide | 0.43 |

| B | NWD-2336 Black Iron Oxide | 0.13 |

| C | Polyglyceryl-3 Diisostearate | 2.00 |

| C | Polyglyceryl-2 Dipolyhydroxystearate | 2.00 |

| D | Fragrance | 0.50 |

In a secondary beaker, introduce A and solubilise NaCl

In the main beaker, introduce B and heat up to 80°C under stirring

At 80°C, stir for 30min

Cool down to 40°C

Add C to B and stir for 5 min

Make the emulsion pouring A into B+C for 15 min

Add D and homogenise

Pleasant, easy-to-spread texture thanks to EstoGel® Green.

Very even skin finish.

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | Caprylic/Capric Triglyceride | 34.00 |

| A | Castor Oil | 34.00 |

| A | Coco-Caprylate Caprate | 5.00 |

| A | Unipure White LC 987 | 8.87 |

| A | Unipure Yellow LC182 | 0.75 |

| A | Unipure Red LC381 | 0.29 |

| A | Unipure Black LC989 | 0.09 |

| B | EstoGel® Max | 6.00 |

| B | Rice Bran Wax | 7.00 |

| B | Polyhydroxystearic Acid | 1.00 |

| C | Silica | 2.50 |

| D | Fragrance | 0.50 |

Anhydrous foundation with a gourmand texture and pick-up. Very soft and silky when applied.

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® Green | 3.00 |

| A | Caprylic/Capric Triglyceride | 14.30 |

| A | COD-8008 TiO2 Cos Disp | 1.75 |

| A | COD-8006 Red Iron Ox Cos Dis | 0.50 |

| A | COD-8005 YLW Fe Ox Cos Dis | 0.25 |

| A | Pearls | 0.20 |

| B | Water | 68.10 |

| B | Phenoxyethanol | 0.60 |

| B | Carbopol® Ultrez 10 | 0.18 |

| C | Fragrance | 0.50 |

| D | Glycerin | 10.00 |

| D | Decyl Glucoside | 0.40 |

| E | Sodium Hydroxide (sol. 10%) | -0.78 |

Innovative texture

Pigments encapsulation

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | OleoShine® Green | 38.00 |

| A | EstoGel® Green | 2.00 |

| A | Ethylhexyl Palmitate | 20.00 |

| B | Isododecane | 20.00 |

| B | Undecane (and) Tridecane | 20.00 |

- Heat A to 80°C and stir for 20 minutes

- Cool to 50°C under stirring

- Add B and mix well

- Pour at 50°C

- Use as a primer for curl and volume

- Wear alone for a natural, bright look

- Shapes and lifts lashes for a wide-eyed effect

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® Green | 4.00 |

| A | Caprylic/Capric Triglyceride | 6.00 |

| A | Ethylhexyl Palmitate | 22.00 |

| B | OleoFilm Green | 3.00 |

| C | Rice Bran Wax | 8.00 |

| C | Beeswax | 7.00 |

| D | Isohexadecane | 20.00 |

| E | Silica | 10.00 |

| F | Intenza Envy | 0.15 |

| F | SunShine Super Golden | 18.32 |

| F | SunShine Soft Bronze | 1.53 |

Add A to a beaker and heat up to 80°C under stirring

At 80°C, disperse EstoGel® Green under stirring for 20 minutes

Add B to A and mix well

Add C to A+B and mix well

Cool to 70°C

Add D to A+B+C and mix well

Add the silica and mix well

Add the glitters and mix well

Transformative texture: from solid to creamy eyeshadow and disapears into powder.

Uniform film formation and enhanced anti-transfer features thanks to our OleoFilm Green

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | Demineralized Water | 50.90 |

| A | Preservatives | 0.60 |

| A | Natpure Film AP | 1.00 |

| B | Butylene Glycol | 3.00 |

| B | Xanthan Gum | 0.30 |

| C | Aminomethyl Propanediol | 1.00 |

| D | Cellulose | 2.00 |

| D | Unipure Black LC 989 | 8.50 |

| D | Unipure Red LC 381 | 1.50 |

| E | Helianthus Annuus (Sunflower) Seed Wax | 9.00 |

| E | Beeswax | 8.00 |

| E | Copernicia Cerifera (Carnauba) Wax | 3.00 |

| E | Stearic Acid (and) Palmitic Acid | 5.00 |

| E | OleoFilm Green | 3.00 |

| E | Dermol MBDD | 3.00 |

| F | Tocopherol | 0.20 |

Add A to the main beaker and start stirring

Premix B and add it to A and mix well

Add C to A+B and mix well

Heat up to 85°C

Add D under vigorous stirring for 20 minutes

Add E to a secondary beaker and heat up to 85°C under stirring

Make the emulsion pouring E on A+B+C+D and stir for 20 minutes

Cool to 40°C

Add F and mix well

Long lasting wear

Fast drying upon application, allowing for easy layering

| Phase | Raw material | Pourcentage |

|---|---|---|

| A | EstoGel® Green | 4.00 |

| A | Caprylic/Capric Triglyceride | 6.00 |

| A | Ethylhexyl Palmitate | 25.00 |

| A | Isohexadecane | 20.00 |

| B | Rice Bran Wax | 8.00 |

| B | Beeswax | 7.00 |

| C | Silica | 10.16 |

| D | Pearls | 19.84 |

Heat up A to 80°C under stirring

At 80°C, disperse the polymer for 20 minutes

Add B and stir until the blend is homogeneous

Cool to 70°C

Add C and stir until the blend is homogeneous

Add D and stir until the blend is homogeneous

Pour into a mold

An ultra-creamy wax stick thanks to the combination of waxes and EstoGel®.

The texture has a double transformation, from solid stick to creamy eyeshadow and disapears into powder.